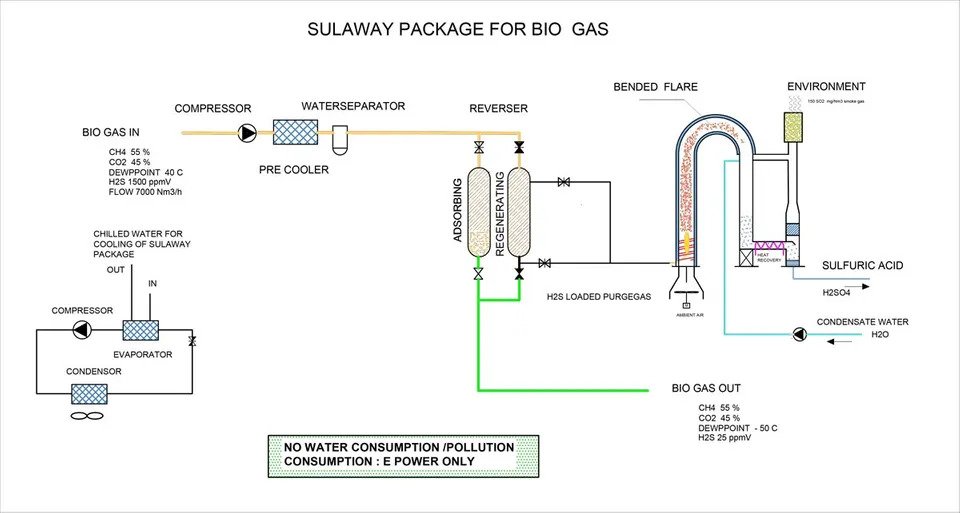

Advantages of Sulaway plant Flow scheme

Advantages SULAWAY plant

- Impregnated Molecular sieve (Sulabead®) instead of active carbons, which means lower maintenance and transportation costs

- Production cost low due to the regeneration of Sulabead®

- Low carbon foot print due to absence of extremely polluting active carbon

- No water required nor wasted water to clean

Drain water is used for production of Sulphuric acid (H2SO4) - At high H2S concentrations the acid production will be profitable

- The complete process is liquid glycol cooled to obtain highest efficiency

- The heat from the chiller can be used for district heating and is higher than the electrical power consumed due to condensation heat of the drainwater

- Low power consumption

Maintenance costs are low due to the long life to the adsorbent and compressor - Due to intensive water removal upstream – no aggressive liquid acids: H2CO3 and H2SO3 – and water-cooled oil cooler, there is a long oil change interval

- The production costs are low due to absence of wastewater or coal

- For maintenance shut down CO2 is used as a safety gas instead of Nitrogen for two reasons: CO2 is ample available and keeps smoke gas free from Nitrogen impurities