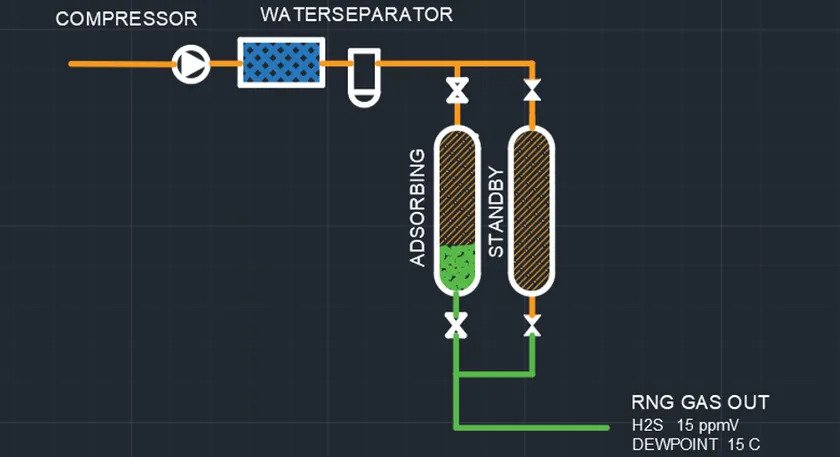

Catalyst polishing Flow scheme

This process is designed to sweeten small sour gas flows. The catalyst is an absorbent which removes H2S. Iron water is a waste product of a sewage plant. Gazpack has developed, in co-operation with manufacturers of sewage plants, an application that transforms the iron water into granular beads. These beads absorb the H2S from sour gas. Fe2O3 + 3 H2S to Fe2 S3 + 3 H2O. The process is not reversible and creates heat during absorption.

The package consists of one compressor, a cooler, a scrubber and two towers with Sulago® beads.

To operate successfully the following precautions are necessary.

Design criteria:

- Diameter (low contact speed causes insufficient absorption).

- Height (crushing pressure)

- Two vessels (heat transfer)

- Stainless steel (hot H2S + H2O is aggressive)

- Drain water is acid, toxic and explosive in contact with water (dangerous: add water not inverse).

This system is suitable for small capacities (<1000 Nm3/h) and low H2S values (<250 ppmv H2S).

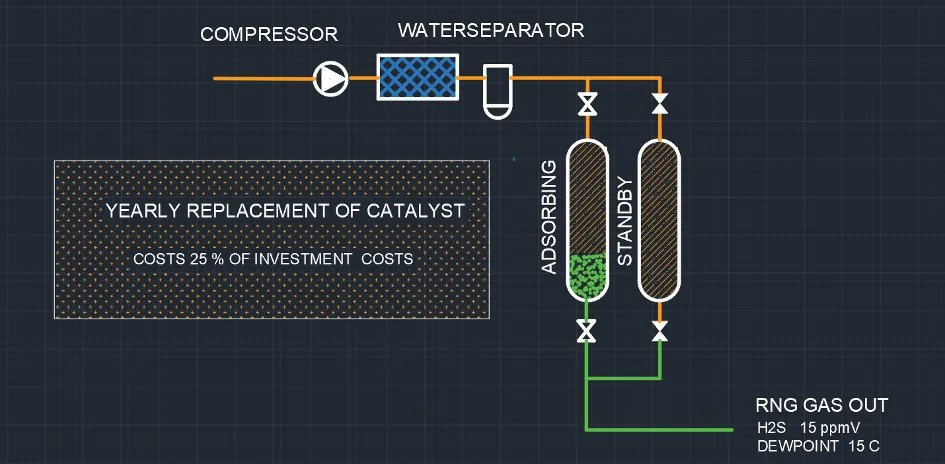

Production costs are high due to:

- The saturated absorbent is a chemical waste product and processing it as such is expensive.

- Cleaning of the vessel is dirty and risky work, environmental precautions are required.

- Price per kilo is high.

The waste absorbent is toxic and is easily flammable and should be stocked under a nitrogen blanket.

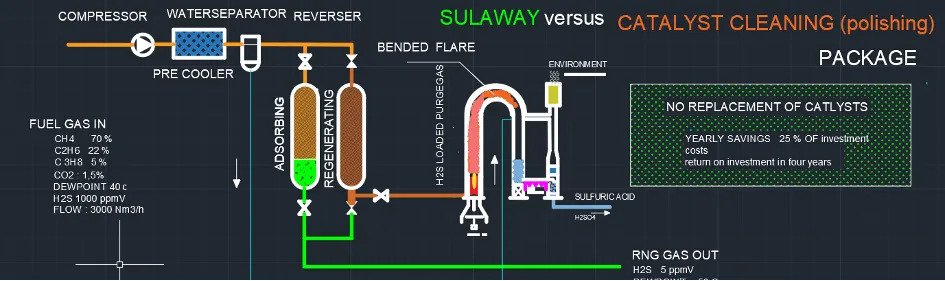

For higher capacities, the Sulaway ® system is the best choice. The investment costs are lower and the system is environment friendly. The H2S is transformed into acid water (0% H2SO4), which is marketable as an environmental friendly product.