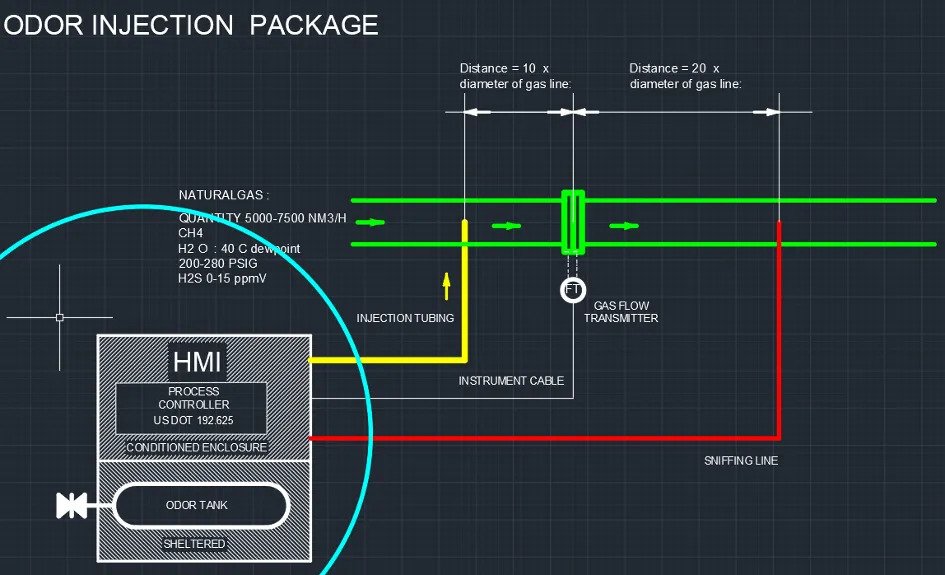

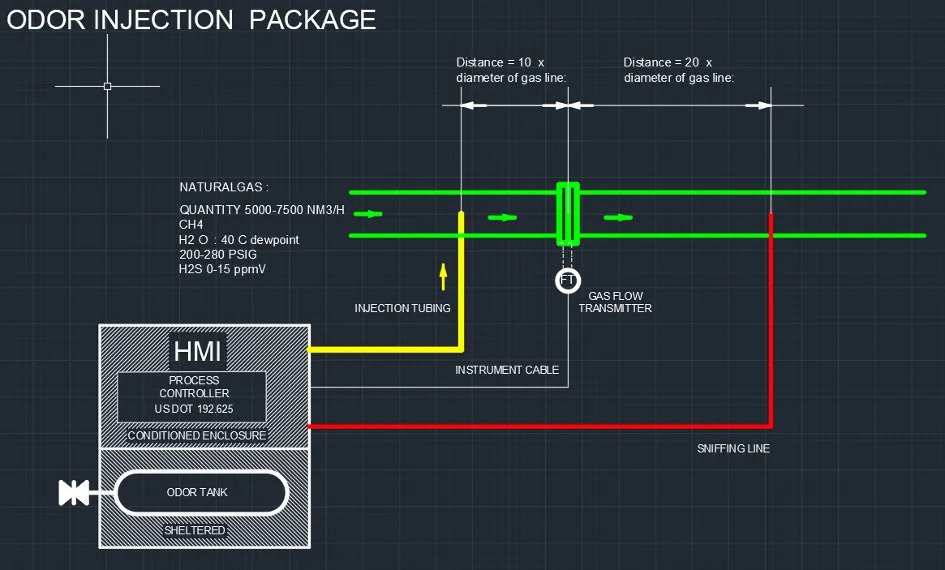

Odorizing unit Flow scheme

Methane is odorous

A leakage in our gas cleaning system will not be noticed, because methane is odorless and therefore will not be detected in its natural form. Inside the Sulaway enclosure a detecting camera is mounted to detect any deformities in the passing gas and can sound an alarm. For environmental purposes the process enclosure is ventilated up to the gas cleaning filter of the flue gas chimney.

The treated (RNG) is odorized up to 16 mg/m3 thiolan (C4H8S). This is a gas with an unpleasant odor warning for leakage of gas pipes, furnaces, etc. Less costly is to use the Sulaway cleaning package and lower the H2S content to 15 ppmV. However most customers want to do the odorizing by a third party, which is called the gate keeper. The keeper checks the Wobbe index and the end client prefers a H2S content lower than 15 ppmV most of the times. The Wobbe index is a combustion indicator; the higher the value the more heat can be generated.

The HMI dashboard is placed in a ventilated enclosure. The controller consists of a gas plunger pump to supply to the controller. The electronic controller is suitable for proportional to flow control or time based flow and has a Modbus for remote communication. The enclosure will be placed on an open frame with an odor tank for liquid thiolan or equal quality. The package must be placed under a roof and for high ambient temperatures, an air-conditioned cooler is required in the enclosure.

Time based flow injection is possible at constant flow, but most packages have a fluctuating supply for which flow measurement and control is available. A sniffing line is necessary for checking the correct odor level.