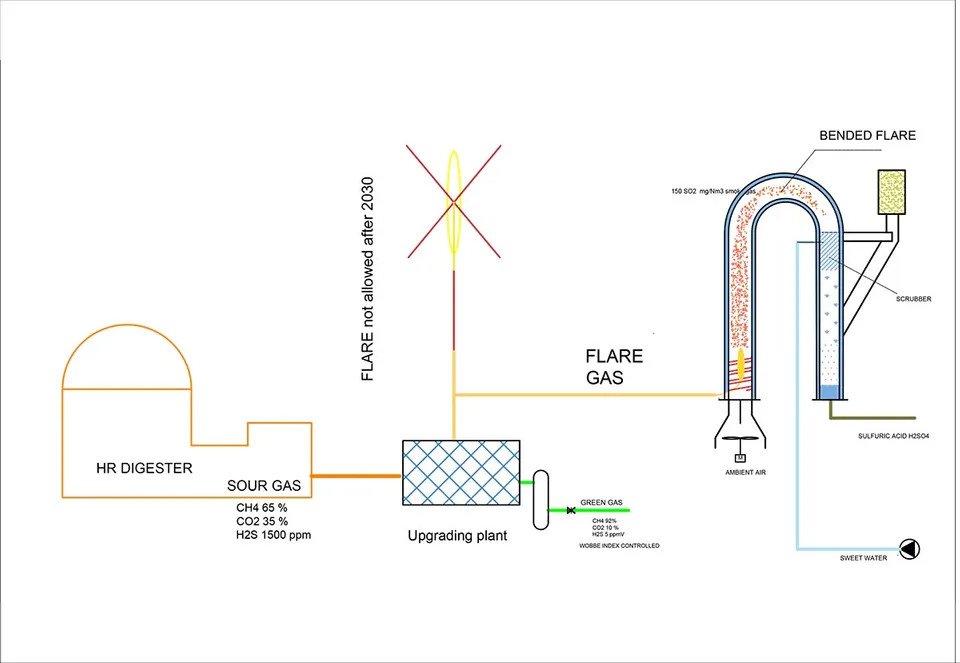

Stop biogas flare Flow scheme

Sustainable friendly to a sulphuric distributor

How does it work?

In a biogas gas plant: The flare gas enters the bottom of the U tube and is ignited by a pilot light fed with propane gas. The flare is bended over 180 degrees and temperature rises up to 1000 °C. At this temperature the H2S is converted into SO2. The gas is cooled down by injection water to transform SO2 into SO3, which is solvable in water and makes Sulphuric acid (H2SO4). H2SO4 has many applications in distributing environment for production such as battery water, production of gasoline, tanning of leather, detergents etc.

Advantage:

Extreme volume reduction: for example: 1500 Nm3/h sour gas (with 2500 H2S ppm) will be quenched down to 15 liters acid water containing 80 % H2SO4.