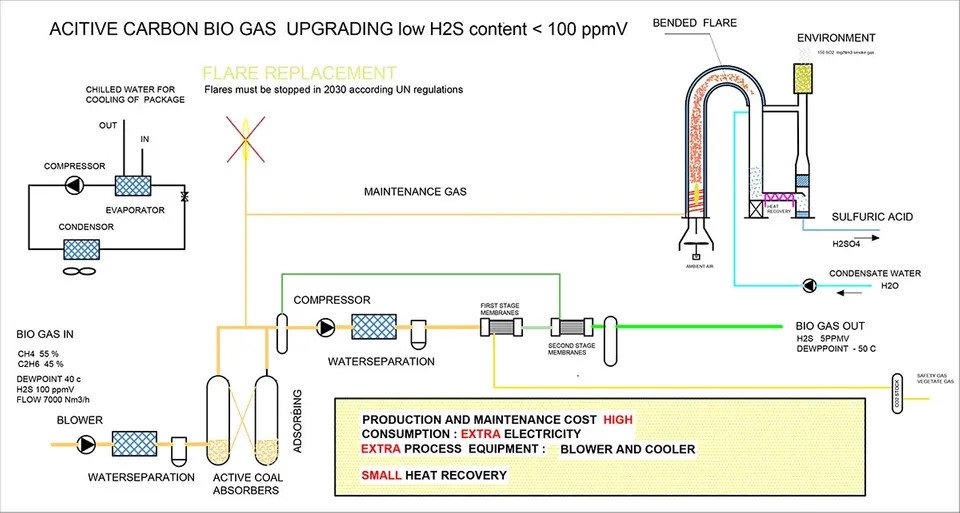

Sulaway versus Biological sweetening plant Flow scheme

Biological H2S removal is a danger for the environment

An amine plant is a cheap investment, but extremely expensive in production and maintenance.

H2S content from 10.000 up to 100 ppmV

Extra investment costs due to process equipment:

- Blower/booster compressor

- One (1) heat exchanger

- Sewage treatment plant to wash water

Production costs:

- Active coal

- Extra electric power

- Water consumption

- Loss of methane (CH4)

Maintenance:

- Daily attention of biologicals

- Sulaway plant checkup each half year for gas compressor

Savings:

- Sewage water plant produces Sulphuric acid (4%)

- Sulaway decreases costs by transforming H2S in sulphuric acid (H2SO: 85%)